What's New

27-09-2025: Support for Deye 3phase inverters added.

07-08-2025: Support for Jsdsolar inverters added.

26-07-2025: WiFi connection + additional features. See useful links

30-06-2025: Wattmeter support added.

29-06-2025: Support for Deye 1phase inverters added.

13-06-2025: Support for Growatt SPF5000, SPF6000 inverters added.

02-06-2025: Support for LuxPower SNA3000-6000 inverters added.

18-05-2025: Wiring diagrams for SV701 and WiFi data logger for simultaneous operation published.

12-05-2025: Support for two PV inputs for PowMr 10.2 kW inverters added.

03-05-2025: Support for DATOU BOSS 6200w inverters has been confirmed. They operate on the Voltronics&Clones protocol. Please note that these inverters have a non-standard connector pinout!

15-04-2025: The website design has been completely updated.

30-03-2025: Support for Anenji 11kW inverters added.

26-03-2025: Support for MUST inverters added.

28-02-2025: Official launch of the website. Support for 4 types of inverters.

Green energy is steadily becoming a part of our daily lives. Many households have already installed small solar power plants, the core of which is a hybrid solar inverter. Often, these are budget inverters manufactured in China or Taiwan.

However, the owners of such systems often face the issue of excess solar generation when the panels produce more energy than is consumed at the moment. We offer an effective solution to this problem with the SV701 device.

Ways to Utilize Excess Solar Energy

1. Using On-Grid Inverters

On-grid inverters allow excess energy to be fed into the external power grid. This is a technically sound solution but comes with several challenges:

- The high cost of such inverters compared to off-grid models;

- Bureaucratic difficulties associated with setting up feed-in to the grid;

- Certification issues. Many budget inverters lack the necessary certifications for grid feed-in;

- The need to purchase additional equipment (bidirectional electricity meters and quality control devices for generation);

- Low feed-in tariffs in some countries;

- Lack of access to the external network in remote areas, during natural disasters, or military actions.

2. Useful Load for Excess Energy

A more affordable solution is to use an additional useful load to utilize excess solar energy. Energy-intensive devices, such as electric water heaters or space heaters, are already present in many homes. However, they have fixed consumption, while the excess energy from solar panels is a variable value, depending on the time of day, weather, and the battery charge level.

Some premium inverters can redirect excess solar energy to an additional port using the SmartLoad function. But budget inverters do not have this function. It was for such inverters that the SV701 device was originally created, which provides control of additional load and utilization of excess energy. Later, we received requests from owners of inverters that have a standard SmartLoad function. It turned out that this function works through the charge-discharge of the battery and is not suitable for everyone. Now we have added support for such inverters.

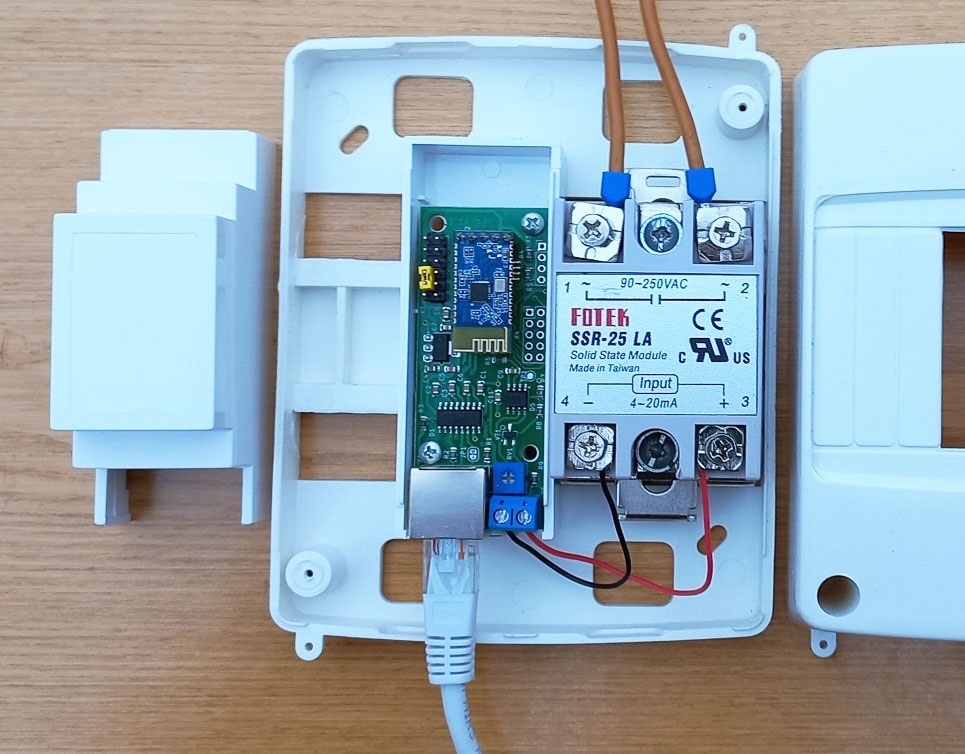

The device controls a solid-state relay and can operate in two modes. The first mode is a standard dimmer with manual output power adjustment. The second mode is a "smart regulation" mode, which allows using only the excess power from solar panels.

Theoretical Foundations

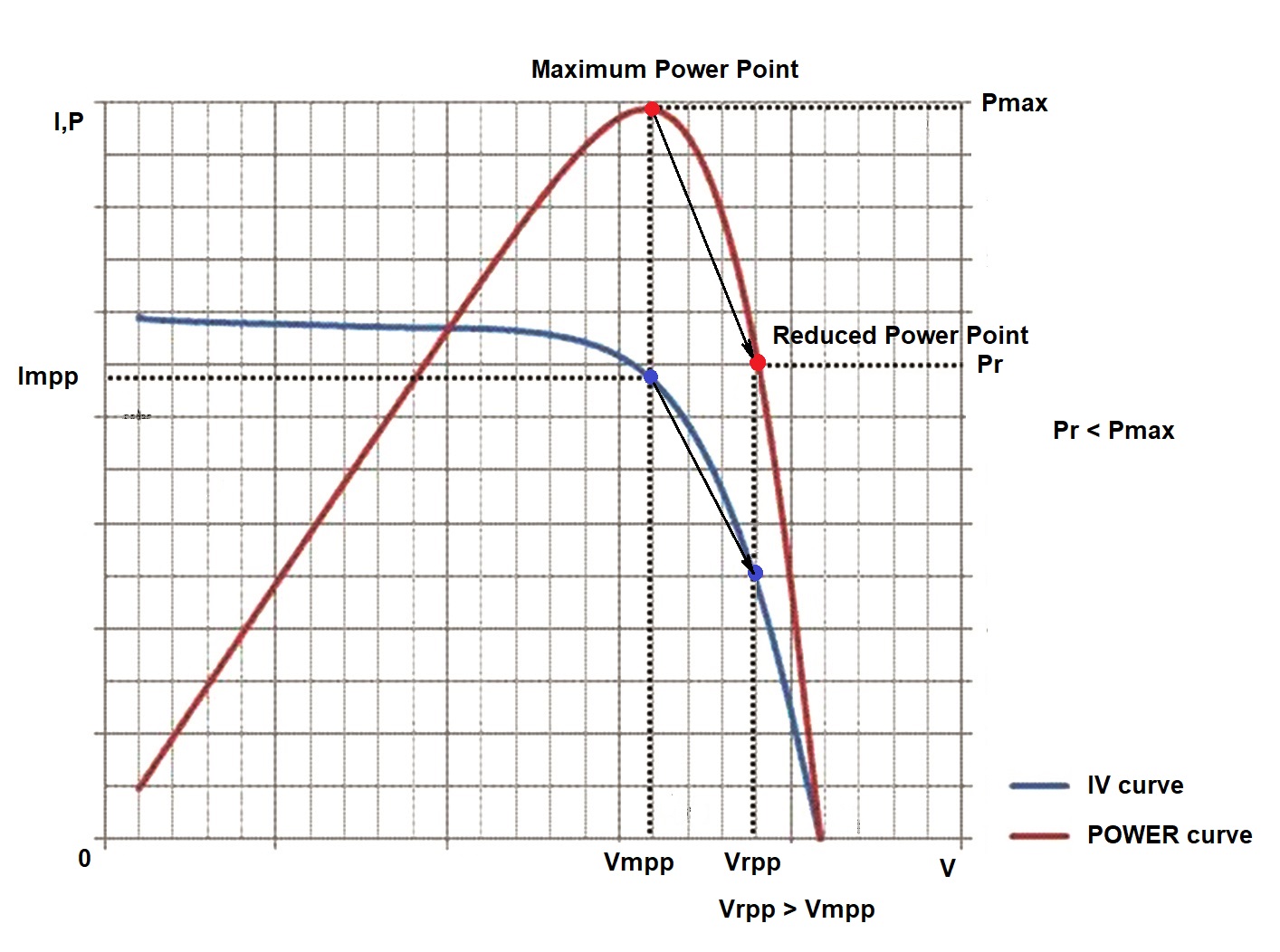

Let's take a look at how it works. Any hybrid solar inverter includes a Maximum Power Point Tracking (MPPT) module, which allows it to extract the maximum power from the solar panels under the current lighting conditions. There are several algorithms for finding this point, and it is not known in advance which specific algorithm is used by a particular inverter. What unites these algorithms is that they all determine the maximum power point on the I-V curve of the solar panel within a relatively narrow voltage range, typically around 0.7–0.8 of the open-circuit voltage of the solar system. All inverters behave similarly when the power generated by the solar panels starts to exceed the consumption of all connected loads. In this case, they "exit" the maximum power point to reduce generation power by increasing the voltage on the solar input. Observe the indicators of your solar inverter when it has sufficient load to utilize all the solar energy. You will notice that the solar input voltage always stays within a certain narrow range during this time. Now observe the inverter when its loads are insufficient to absorb all the solar energy. You will see that the voltage rises out of that narrow range.

This behavior is illustrated in the figure below. The graph shows typical current-to-voltage and power-to-voltage dependencies for a solar element. It demonstrates how the inverter shifts the power extraction point in the case of excess solar energy.

This principle is utilized by SV701 to dynamically increase or decrease the inverter's load, bringing the system back to the maximum power point. As mentioned earlier, there are several algorithms for finding the maximum power point. The simplest one is called the Fixed Voltage Method. It fixes the voltage at a single point within the 0.7–0.8 range of the open-circuit voltage. While this method is slightly less efficient than others, it significantly outperforms them in reliability and response speed. SV701 operates using this method and establishes an external maximum power point tracking loop for the inverter! The device queries the inverter once per second and dynamically adjusts the load.

h2>The Water Heater Is Also a Battery :)

Let’s take a closer look at an energy consumer like an electric water heater. Many solar inverter owners consider it a cumbersome and energy-hungry load for their system. If the water heater is connected directly to the inverter, this is indeed the case. However, using a water heater together with our SV701 offers a different perspective. Hot water is always needed for household use. Heating 100 liters of water by 50 degrees (from 20°C to 70°C) indeed requires a significant amount of electricity—around 5.8 kWh. But the water heater can also be viewed as an energy storage device! With good thermal insulation, it retains heat energy for a long time. At the same time, the cost of such a 5.8 kWh storage unit is an order of magnitude lower than that of a comparable electric battery pack. Therefore, it makes perfect sense to divert “excess” electrical energy into it and then use the hot water as needed. Moreover, SV701 enables this to be done in a “smart mode,” preventing inverter overload.

Other alternative loads for the SV701 can include different types of heaters. For example, an auxiliary heater for home heating during the cold season or a pool heater during warmer months.

Device Operation

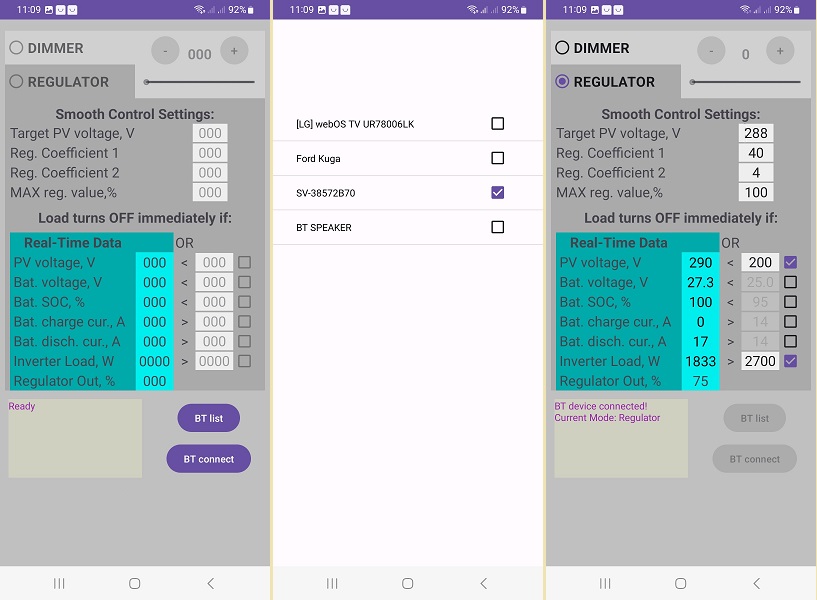

In firmware versions 1.xx, the device operation modes are controlled using jumpers on the board and the BtControl700 Android app on a smartphone. In the newer 2.xx firmware versions, all control is performed via the BtControl702 app.

Possible wiring diagrams are shown on this page. First, connect the SV701 to the inverter without connecting the load to the solid-state relay and make sure the device is receiving power. This can be verified by the status LEDs located on the RJ45 connector. The left LED indicates the data request transmission, while the right LED shows the inverter’s response. The colors of the LEDs may vary depending on the connector version. Data exchange occurs once per second. If neither LED is blinking, the device is not receiving power from the inverter via the cable. Check the cable pinout. If only the left LED is blinking, the device is not receiving a response from the inverter. The cause may again be incorrect pinout or an incompatible communication protocol. The communication protocol can be changed later in the BtControl702 app.

Control via Android App

The latest version of the BtControl702 Android app can be downloaded from the downloads page. First, establish a Bluetooth connection to the device using the standard Android system tools. Start a device search — your SV701 will appear as SV-XXXXXXXX, where the last characters represent the device’s serial number. If you purchased the Bluetooth module separately, it will initially appear as JDY-31-SPP. Pair with this device using the password 1234.

During the pairing process, Android may request permission to access your location. Don't be alarmed — this is a standard Android requirement, as scanning for and pairing with Bluetooth devices can potentially be used to determine the user’s location. Google requires location access permission for Bluetooth Low Energy (LE) device scanning and pairing. Please note that our app does not use or collect your location data. The permission request comes solely from the Android system as a security and privacy measure.

Start by tapping the BT List button, which opens the list of available Bluetooth devices. Check the box next to your device and return to the main screen using your phone’s system back button. This action only needs to be done once — the app will remember the paired device for future use.

Then tap the BT Connect button, and your smartphone will establish a connection with the SV701 device.

Let’s go over the controls and indicators. In the upper left corner of the screen, there is a toggle between Smart Dimmer and Smart Regulator modes. The first mode allows you to set a fixed load level using a slider or buttons on the smartphone screen. Once configured, all parameters are saved in the device’s memory and it will continue operating with those settings even after the smartphone is disconnected or power is cycled. Note that the 0–100% scale represents the control signal level sent to the solid-state relay. The actual response curve of the relay is highly nonlinear and depends on the type of relay — and even on the individual unit. For example, if you want to achieve 50% of the nominal load power, this should be verified using external measurement devices or the inverter’s readouts, since that level may be reached at 40% or 60% of the control signal for different relays.

The next mode is the main one — Smart Regulator. At the top of the screen, there are four key settings for two PV inputs of the inverter. If your inverter has only one PV input, the settings for the second input are ignored. The first setting is Target PV voltage — the PV input voltage that the regulator will attempt to maintain by increasing or decreasing the load. The next two settings are the controller coefficients. The regulator is implemented as a type of nonlinear PID controller. Classic PID controllers are designed for linear, time-invariant systems. In our case, the system is both nonlinear and time-variant, since the voltage response step changes depending on the level of solar irradiance. For example, in our test system, changing the PV voltage by 10V around the MPPT point on a cloudy day requires only 40–50W of load adjustment, while under full sun it may require ±800–1000W. That’s why the device uses a custom nonlinear control algorithm developed in-house — the specifics of which are proprietary. Two coefficients, K1 and K2, are available for adjustment. Another important setting is the maximum load limit. If your load is too powerful when fully enabled, this setting allows you to cap it, and the regulator will never exceed the defined value during operation.

The next seven parameters are designed to immediately disable the load when certain conditions are met. This is necessary for prioritizing energy distribution by the inverter, and for fast reaction to external events. On the left side, you see real-time values coming from the inverter. On the right — adjustable threshold values. To enable a specific parameter for operation, make sure to check the box next to it.

SV701 Configuration

Let’s take a look at the general strategy for configuring SV701. First, we should mention the metrological characteristics of low-cost Chinese-made solar inverters. Unfortunately, they are not very accurate. This is confirmed both by user feedback on specialized forums and by our own measurements. Discrepancies between the readings of external measuring instruments and those of the inverters themselves can be significant. Fortunately, the PV input voltage is usually measured quite accurately by the inverter, as is the battery voltage. However, current measurements are often far less reliable. For example, the inverter may show a battery discharge current of 15A, while current clamps and the battery’s BMS show zero consumption. The same applies to the current on the solar input — the inverter might report zero current and zero power, even though 0.5A is actually flowing, which at 300V equals 150W of solar input. Interestingly, despite this inaccuracy, the inverter as a closed-loop system functions well — it redistributes energy where needed. The issue lies primarily with the display readings and the data shared via communication interfaces. The reason for this behavior is unclear. Accurate measurement of these values is not a technically difficult task, so perhaps it’s marketing — inexpensive inverters are not supposed to be too good, so that users are tempted to buy more expensive models :)

Now let’s return to the strategy itself. Our strategy is not to interfere with the inverter when it is operating near the maximum power point, and to add load only when it goes beyond that zone by voltage. As mentioned earlier, the indication that the inverter has left the maximum power point is an increase in the PV input voltage. Therefore, the first step is to determine the maximum power point voltage for your system. This can be done quite easily: check the voltage at the maximum power point specified for your solar panels.

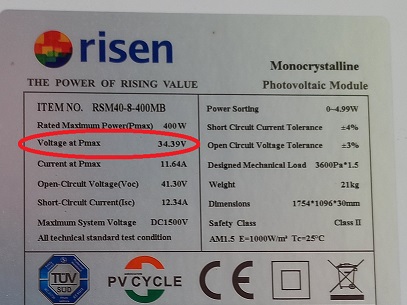

Then multiply this voltage by the number of panels in your string. This will give you the approximate maximum power point voltage for the entire string, which the inverter will attempt to maintain. For example, with a string of 4 panels like the ones shown above, you get 34.39 * 4 = 137.6V. In reality, this voltage may vary slightly depending on temperature and cable resistance, but at this stage of configuration, these small deviations are not critical. Later, during actual operation, this offset can be fine-tuned if necessary.

The target voltage should be set 2–10% higher than the maximum power point voltage of the string. The greater the difference between the SV701 target voltage and the string's maximum power voltage, the lower the efficiency of excess energy utilization. However, setting these values too close is also undesirable, as the SV701 device may start competing with the inverter in finding the maximum power point. For the example string of four panels, you can set this value to 140–145V.

Next, let’s talk about the coefficients. For most systems, you can leave these coefficients at their default values. Tuning the coefficients of a classical PID controller is already something of a dark art :) — and it’s even more so for a nonlinear one. We’ve tried to simplify this task for users by fixing some of the coefficients in our algorithm. The remaining two are available for adjustment. In control theory, the difference between the target value and the current value is called the control error. You can think of it this way: K1 has more effect when the error is large, and K2 when the error is small. Each coefficient can range from 1 to 100. The higher the value, the faster the response, but also the greater the chance of overshoot. So, start with small values, observe how the system performs, and find a compromise between speed and stability.

For inverters with two PV inputs, the above settings must be configured separately for each input. If one of the inputs is not used, all three values for it should be set to zero.

This parameter sets the maximum output value of the regulator. Note that the percentage reflects the level of the control signal, not the actual load level. As mentioned earlier, this is because SSR LA relays from different manufacturers — and even different batches from the same one — can have varying response characteristics. The regulator’s output range is designed to cover the full range of such variability. You may want to adjust this parameter from the default 100% in two cases. First — if you want to limit the load to a value lower than the full capacity of your water heater. For example, if your heater is rated at 2kW but you want to cap it at 1kW. Second — to improve regulation speed for certain relays that reach full load “too early.” For instance, some relays may reach full output at just 60% control signal level. In both cases, you should temporarily switch the device to Smart Dimmer mode and manually adjust the control signal while monitoring inverter readings to find the appropriate level. In the first case, find the point where the inverter load increases by +1kW. In the second, find where the load increase equals the full power of the heater. Once identified, enter that value into the MAX reg. value field.

Next, let’s look at the threshold parameters. These are optional but highly recommended. When a checkbox next to a parameter is enabled, the SV701 will instantly disable the load if the condition between the set threshold and the inverter’s real-time data (shown in green in the app) is met. If the threshold is exceeded, the corresponding parameter will turn red in the display.

As a threshold voltage for disabling the load, it's reasonable to set a value 5–30% lower than the maximum power point voltage of your string. This way, a sudden increase in AC load will cause a drop in PV input voltage, and SV701 will instantly disconnect its ballast load. For our example with a string of four panels, a suitable value would be around 100–120V. If your inverter has two PV inputs but only one is used, uncheck the box next to the unused input.

Battery voltage is reported by the inverter with fairly good accuracy. Indirectly, this value reflects the state of charge of your battery. If you want to prevent load activation when the battery is not sufficiently charged, you can enable this limiter and set an appropriate threshold. Keep in mind that LiFePo4 batteries have a relatively flat voltage curve across most of their usable range.

This parameter represents the battery's State of Charge (SOC). A reasonable threshold would be around 90–97%. Near the end of the charging cycle, the battery is charged with low current and the system may already have excess solar power. Unfortunately, this parameter can be quite inaccurate if calculated by the inverter itself. Many Chinese inverters seem to estimate SOC based on battery voltage assuming lead-acid characteristics. In that case, it’s best to leave this limiter disabled. However, if your BMS provides a more accurate SOC value over a communication cable, then this limiter can be safely used in operation.

These two parameters — battery charge and discharge current — are theoretically more natural indicators of battery usage. However, as mentioned above, budget inverters often report inaccurate values here. We recommend monitoring your inverter and, if possible, comparing its readings with clamp meters or BMS data. If you're lucky and your inverter measures these currents accurately, then you can safely enable these limiters. For example, you might set both charge and discharge limits to 5–15A. If your battery has a large capacity, you can increase the threshold to 10–30A or simply disable these limiters using the checkboxes.

This parameter displays the inverter's AC load in watts. If you want to avoid overloading the inverter, you can set a threshold value in the app. A reasonable limit would be about 70–80% of the inverter’s maximum output power. Once this limit is reached, the SV701 load will be immediately disconnected. For example, if the fridge, air conditioner, and microwave are running simultaneously and push the inverter close to its limit, SV701 will disconnect the boiler and reconnect it once the total load decreases.

This shows the current state of the SV701's control output. You can use this value to observe how the device is dynamically managing the load.

Once all settings are configured, you can exit the app. The device will save them in its memory and will operate based on them. Later, you can reconnect via Bluetooth at any time to monitor the system's operation or make any adjustments.

Examples of Setup and Operation

This video demonstrates the setup and subsequent operation of a test system consisting of a 4kW Anenji inverter, 400W Risen panels, and a 7kWh battery. The panels are arranged in a 2x4 configuration. The panels are placed on two roof slopes, East-West, with 4 panels on each slope. The inverter is connected to a 900W water supply pump and a 1.7kW water heater via the SV701. After establishing the connection, the device is configured from the default settings for the specific system. Following this, the device puts the system into optimal solar energy harvesting mode. The water pump is activated at 1:43, and deactivated at 2:25. The system operates these actions accordingly.

Below are the graphs showing the operation of our other test system. This system consists of a Jesudom VM4 Twin 4kW inverter, 8 Risen 400W solar panels connected in series, and a 7kWh battery. The load of this system is the electrical grid of a typical residential house. Among the high-power consumers are a water heater, a water supply pump station, a microwave oven, and an air conditioner.

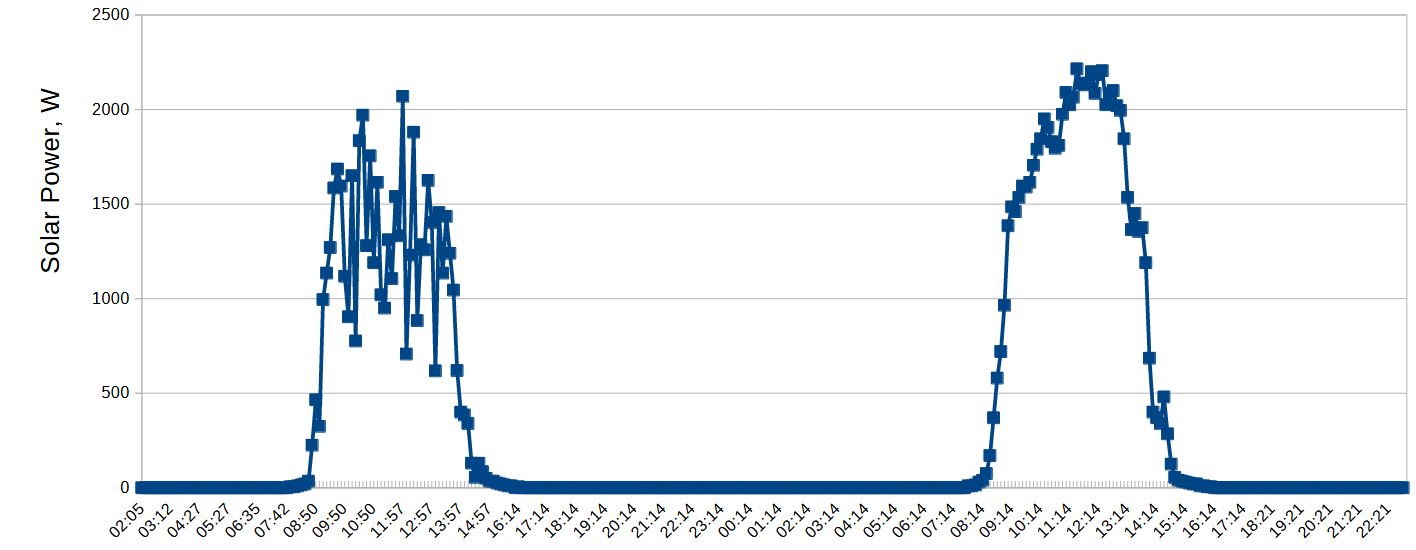

The first graph shows the utilization of solar energy by our test system over two consecutive sunny days. Power was measured at the solar input using an external DC wattmeter. On the first day, the system operated with the SV701 turned off, and on the following day, with the device turned on. From the graph, it is clear that without the device, much potentially available energy remains unused.

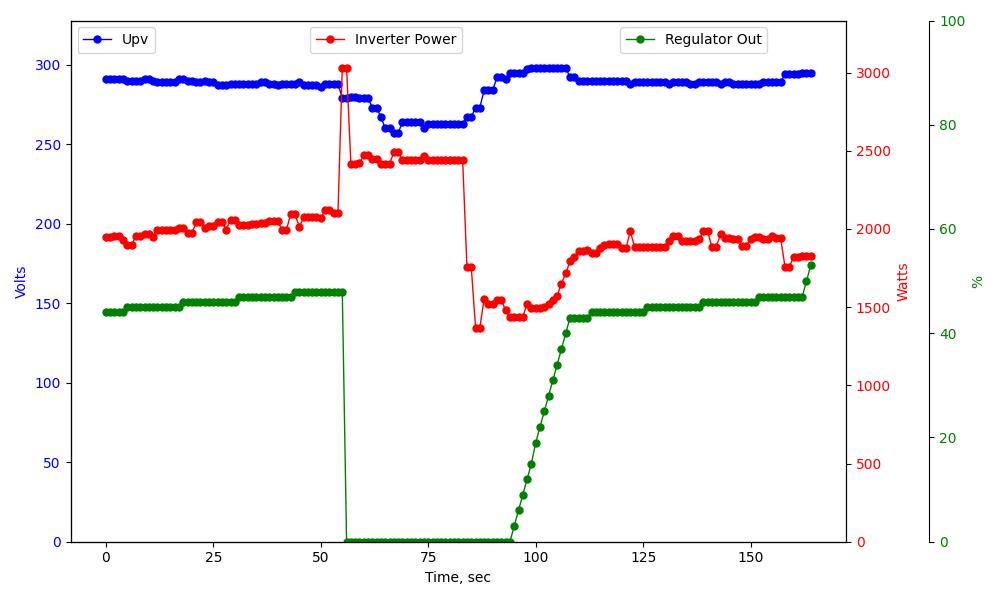

The next graph shows the dynamic behavior of this test system. During system operation, the system maintained the solar input voltage around 290V by partially loading the water heater (about 40%), which allowed drawing about 2000W of solar energy at that moment. At the 55th second, the pump station motor turned on, which sharply increased the system's consumption to 3000W. The SV701 device instantly (2-second delay) responded by completely turning off the water heater, reducing consumption to 2500W. At the 84th second, the pump turned off, and the system gradually added the water heater load back to the previous level, with total consumption around 2000W.

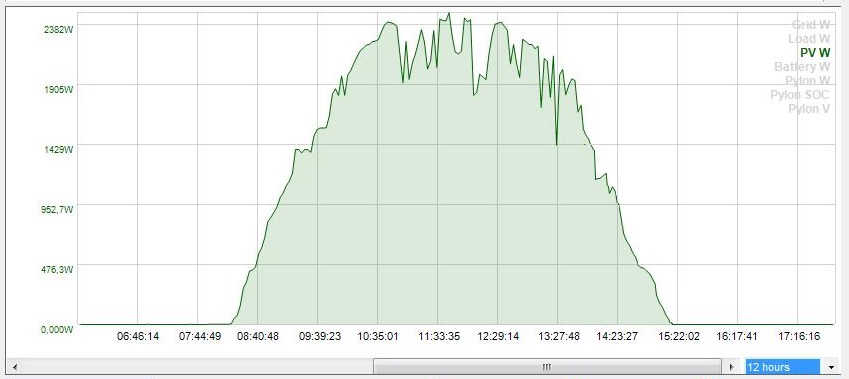

Below is the graph of the solar input power of this test system, taken using the MultiSIBcontrol program. It was operating in its normal mode simultaneously with the SV701 device. The graph shows that the system effectively gathered energy from a winter sunny day. How to combine the operation of the SV701 and the MultiSIBcontrol program is explained here.

Compatibility

The SV701 device is theoretically compatible with any hybrid inverters, regardless of their power and output voltage (120V or 230V). The main requirement is support for the data exchange protocol via the RS-232 port, either directly or through an RS-232/RS-485 converter. Possible connection options for different types of inverters are shown on this page.

Inverter Protocol Features

There is information that, despite the large number of budget Chinese and Taiwanese solar inverter brands, all of them are produced at a few main factories as OEM products. Therefore, inverters from different brands, with minor external differences, may have identical internal electronic boards and use the same communication protocols. However, it is possible that models from the same brand may have different protocols.

The most common protocol is the PIP Solar protocol in various versions. Many inverters from brands like PowMr, Anern, Daxtromn, and several other less common brands operate using this protocol. The SV701 device works with such inverters when selecting the inverter type Voltronic&Clones.

However, some manufacturers have their own protocols. As the project has developed, we have already added support for some of these protocols. Currently, the SV701 device supports 12 different inverter protocols!

Anenji inverters use their own Modbus RTU protocols. The protocols for 4/6kW inverters and 11kW inverters are different. To work with these inverters, select the inverter type as Anenji 4/6kW or Anenji 11kW. There is also information that this protocol is used by EASUN SMG II, ISOLAR SMG II, and POW-HVM-5.5H-48V inverters.

Although many PowMr inverters can provide information via the PIP Solar protocol, their default wifi data logger communicates using their own Modbus RTU protocol. We are unsure which combinations of these protocols might be present in different inverters of this brand. Therefore, we have also added support for this protocol. To select it, set the inverter type as PowMr Modbus.

SRNE inverters have their own Modbus RTU protocol. Additionally, these inverters provide a different RS-485 interface on the RJ45 connector. Therefore, a simple interface converter and an external 12V power supply will be required. The protocol has been tested on the HF2430S60-100 inverter. The protocol and schematic should be compatible with other inverters in this series. To select this protocol, set the inverter type as SRNE.

MUST inverters also use their original Modbus RTU protocol, and they also output RS-485 on the connector. Therefore, an RS232-RS485 interface converter and an external 12V power supply will be required for connection. The protocol was tested on the PH18-3024 PLUS inverter. This protocol should work with other MUST series Ph1800 inverters. Based on the indication in the default SolarPowerMonitor program, the manufacturer includes many of their models in this series. To select this protocol, set the inverter type as MUST.

You must select the appropriate protocol in the application to connect to the LuxPower SNA3000-6000 series inverters. You must use a router if SV701 will work simultaneously with the data logger.

You must select the appropriate protocol in the application to connect to the Growatt SPF5000, SPF6000 inverters. These inverters have independent RS485 and WiFi data logger ports. Therefore, SV701 can work simultaneously with the data logger without using additional devices.

You must select the appropriate protocol in the application to connect to the Deye 1phase series inverters. These inverters have independent RS485 and WiFi data logger ports. Therefore, SV701 can work simultaneously with the data logger without using additional devices.

You must select the appropriate protocol in the application to connect to the Jsdsolar J4000, J5500inverters. Due to the protocol features, the YR-8103 router is not compatible with these inverters. Simultaneous operation of the SV701 and statistics collection devices (Solar Assistant, Home Assistant) can be organized using "listener mode".

To connect to Deye 3phase inverters, you must select the appropriate protocol in the app. These inverters have independent RS485 and WiFi ports on the data logger. Therefore, the SV701 can operate simultaneously with the data logger without the need for additional devices. A three-phase SSR relay is required for load control.

We plan to regularly expand the list of supported protocols. Firmware updates and the update utility will be available on this page.

Useful links

Disclaimer

We guarantee that our equipment will function as described on this website, provided it is correctly installed and operated.

However, the responsibility for proper assembly, connection, and usage rests entirely with the user. We are not liable for equipment damage, system malfunctions, data loss, or other harm caused by violations of instructions, use of the device in unsuitable conditions, or tampering with its design.

The use of our kits is at your own risk. Before starting, ensure you understand all aspects of the assembly process and subsequent system operation. If you have doubts or lack sufficient experience, we recommend seeking professional assistance.